|

|

|

|

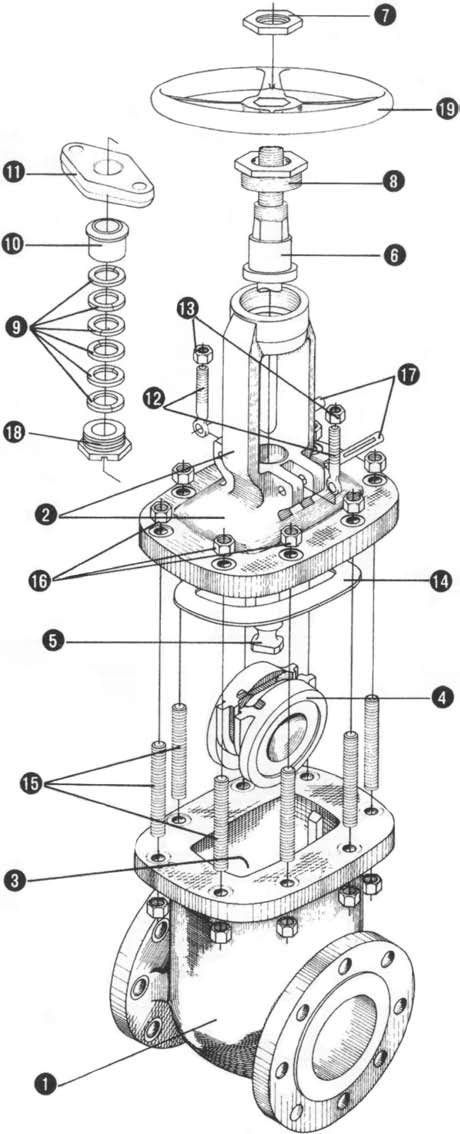

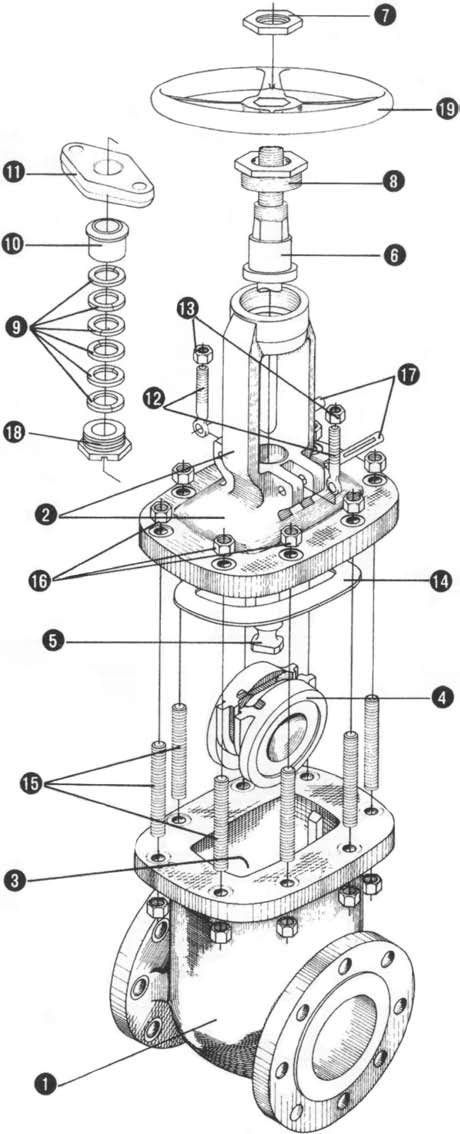

| Crane Class 150 Outside Screw and Yoke |

|

SKU: CR_150

|

| Description and Specs |

Gate valves serve as efficient stop valves with flow in either direction. They are commonly used where a minimum pressure drop is

important. Throttling is not recommended because partially open gate valves exhibit flow characteristics not conducive to accurate

and consistent flow control. Also, the valves may be damaged by the high velocity across the seats. They function best fully open or

fully closed.

Crane gate valves offer the ultimate in dependable service for steam, air, gas, oil, oil vapor, and high pressure installations. All have straight through ports to assure minimum turbulence, erosion, and resistance to flow. They are available in a wide variety of trims.

Size Range:

2 through 24 inches

(50 - 600 mm)

Pressure Temperature Rating

Carbon Steel

ASTM A216 Grade WCB

285 psi @ -20°F to 100°F

(20 bar @ -28°C to 37°C)

1. Body: Body is cast to provide liberal strength to meet operating conditions and to permit unobstructed flow. Turbulence, erosion and pressure drop are minimized.

Flanged End-Crane cast steel gate valves are available in flanged end and butt weld ends. All flanged and butt welding end valves are designed to conform to ASME B16.5 and ASME B16.34 standards.

2. Integral Yoke & Bonnet: Some designs incorporate a two-piece bonnet and yoke. All bonnet assemblies are cast and finished to the same exact-ing tolerances as the bodies for accurate alignment of stems and ease of sealing. Bonnet joint varies from flat face gasket-joint to ring-type bonnet joint, depending on class.

3. Seat Rings: Seat rings are seal welded to eliminate leak path behind rings and for long trouble-free service. The surfaces are precision ground to fit accurately with the disc.

4. Disc: Crane\'s one piece flexible disc provides accurate alignment of mating seating surfaces so the valve can absorb piping strains without leakage. Also, it avoids any tendency to stick in the seated position.

5. Stem: The tee-head disc-stem connection prevents lateral strain on the stem for smooth, easy operation. Accurately cut threads engage the yoke sleeve for positive control of disc position.

6. Yoke Sleeve

7. Handwheel Nut

8. Yoke Sleeve Retaining Nut

9. Packing: Packing contains corrosion inhibitor to avoid stem pitting.Stuffing box is deep, assuring long packing life.

10. Gland: Gland is a two-piece ball-type which exerts even pres-sure on the packing without binding the stem.

11. Gland Flange

12. Gland Eye Bolts: Eyebolts swing aside for ease in repacking the stuffing box.

13. Gland Eye Bolt Nuts

14. Bonnet Gasket

15. Bonnet Studs: Number is dependent on valve size and class.

16. Bonnet Nuts: Number is dependent on valve size and class.

17. Gland Eyebolt Pins

18. Bonnet Bushing

19. Handwheel: Crane gate valves can also be supplied with gear or motor operators.

20. Hydraulic Grease Fitting: Hydraulic grease fitting provides for lubrication of yoke sleeve bearing surfaces (not shown).

|

|

| Material of Construction* | |

|---|

| Description | Material | | Body | WCB | | Bonnet | WCB | | Seat Rings | Hardfaced | | Disc | CA-15 or 13% CR Overlay | | Stem | 410 SS | | Packing | Graphite | | Bonnet Gasket | Corrugated Soft Steel or Steel/ Stainless Steel w/Graphite | | Back Seat | 410 SS | | Yoke Sleeve | D2 Ni-Resist | | Retaining Nut | Malleable or Steel | | Gland | Steel | | Gland Flange | Steel | | Eye Bolt | Steel | | Eye Bolt Nuts | Steel | | Pins | Steel | | Bonnet Studs | A193 Gr. B7 | | Bonnet Nuts | A194 Gr. 2H | | Handwheel | Malleable, Ductile or Steel | | Handwheel Nut | Ductile or Steel | | I.D. Tags | SS | | I.D. Pins | Steel | | Spacer | Steel | | Grease Fittings | Steel |

|

| |

|

©

2003-2009 Industrial Process and Sensor. All rights reserved.

All product names throughout this website are trademarks of their respective holders.

|